The cages used to protect workers from robots are safer when one or more types of interlocks are installed. Interlocks are a type of switch/sensor that signal the robot controller to go into a safe position and power down when the door is opened. They are an important component of robotic cell safety, and of other complex automation systems, too.

Robotic interlocking systems ensure everything is brought to a safe stop before anyone enters a cell, whether to change a tool, clean a sensor, or resolve a material jam.

This blog provides an overview of interlocking systems, but is not intended to replace the various safety standards outlined in ISO 10218/ANSI/RIA R15.0, ISO 13849, and ISO 14119.

Automated machinery can pose a threat to human workers. Mechanisms move quickly, and there are often pinch points, such as the area between a belt and a roller or pulley. It might seem obvious that limbs and fingers should be kept out, but when operators are under pressure to hit targets, they may take shortcuts to resolve problems. Guards are installed to prevent this and to protect against flying debris, fluids, and high-voltage equipment.

Robot cells are hazardous because it’s not always obvious where the robot arm is going, and these robotic arms can potentially crush anyone who gets in their way.

Safety interlocks signal the robot or other machine controller that someone will be entering their hazard zone. They let the machine, cell, or robot come to a safe halt before the person enters this dangerous area, and they prevent the system from being restarted while the person is still there.

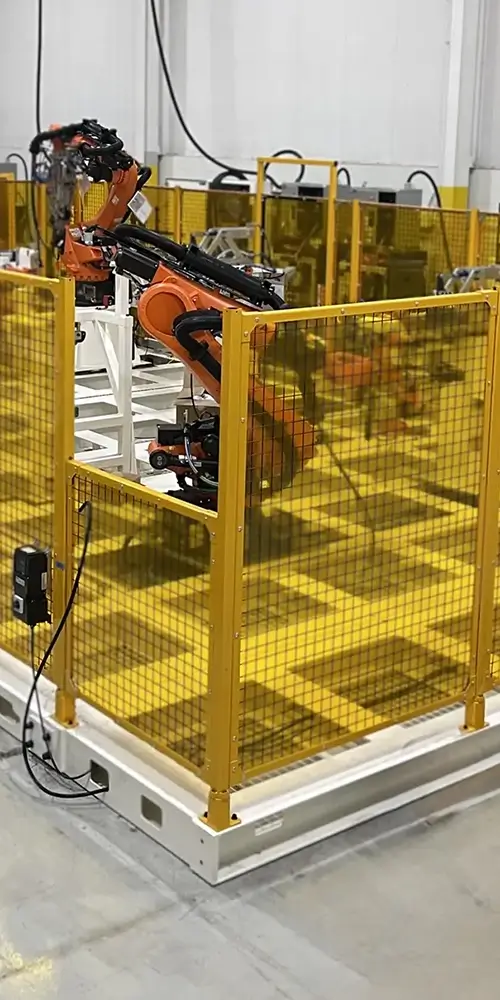

Hard guarding refers to the use of robust wire panels and similar systems to keep people away from hazardous moving equipment. Hard-guarded interlocks mount on the door panels and control access to the inside of the cell.

Hard-guarded interlocks are mostly electromechanical switches where the bolt mechanism is managed by the cell controller. When an operator needs to enter the cell, they press a button that tells the controller to shut everything down safely. Once this is done, the controller allows the handle to be opened.

A variation used on some industrial equipment is the trapped key interlock. The operator takes this key from a special lock on a control panel, which tells the controller to shut everything down. The key is then used to unlock the access gate.

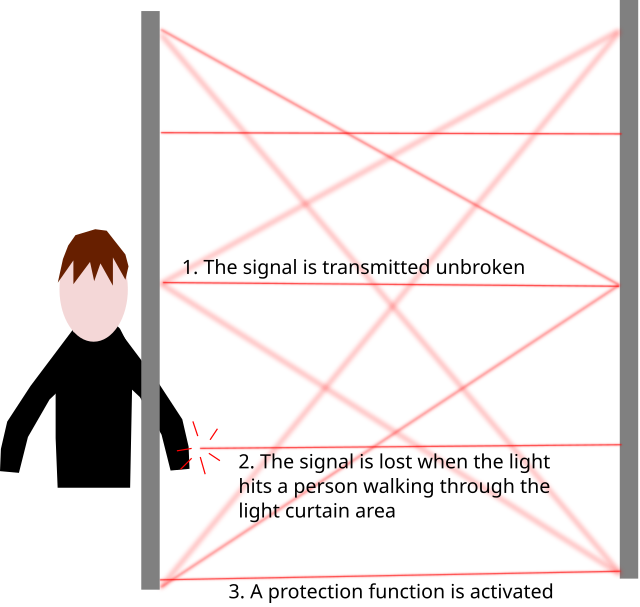

Light curtains are a form of presence sensing. They are often used on machines, such as presses, where an operator needs to reach in regularly.

Light curtains comprise a light-emitting strip and a light-detecting strip, mounted on opposite sides of a gap or opening. If light reception is interrupted, as when someone reaches in through the gap, the controller will disable motion. As such, they are considered secondary rather than primary guarding methods.

A weakness of light curtains is that someone may accidentally point in between the emitter and detector, causing an unnecessary stoppage.

Pressure-sensitive interlocks are another form of presence-sensing, secondary safety devices. They are mats placed on the floor in front of a machine. If someone stands on the mat, a signal goes to the machine controller, which stops the machine motion.

Pressure-sensing mats are often used in front of assembly equipment, sometimes in conjunction with other devices like finger presence monitors. They might also be used in robot cells to prevent the system from being reactivated while someone is inside.

The primary disadvantage of pressure-sensing mats is that they can be fooled by adding weight.

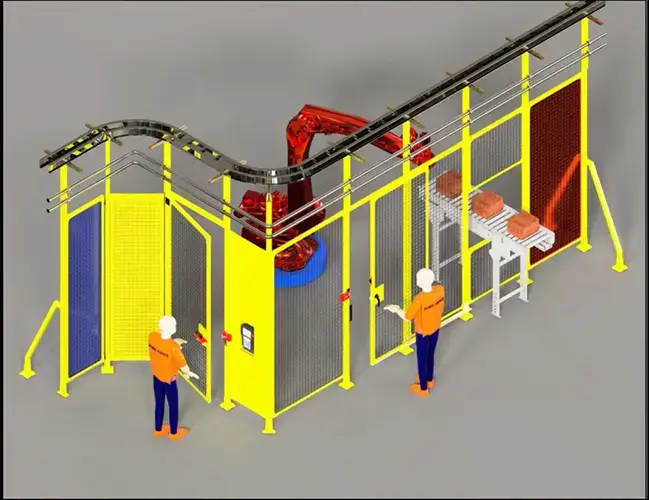

Zone-selective interlocking systems are used in larger and more complex robot cells and other pieces of automated equipment. Their purpose is to make one region safe while allowing other regions to continue running.

An example of when this approach might be taken is a complex packaging cell. Workers might need frequent access to the label printing equipment without stopping the entire cell or line. To address this, there could be a separate zone around the rear of the labeling equipment, accessed through either a dedicated key or push button. When the operator needs to go in, they use this interlock to tell the controller to disable the equipment they will be working on.

Interlocking systems help make robotic cells and other automation equipment easier and safer to use. They can also reduce downtime, but their implementation requires careful thought and planning.

Our advice is to perform a thorough risk assessment and hazard analysis well before implementation. This assessment will help identify potential problems that weren’t otherwise seen and determine possible improvements.

You should also pay attention to:

By offering custom machine guarding solutions, ROBO FENCE® helps manufacturers protect workers while maximizing productivity and efficiency.

All safety fencing systems are engineered and manufactured in the United States through our partner, Square Group, and customized for complex or high-risk environments. From design to implementation, our team is here to help you every step of the way.

Contact us today to learn more about our solutions, or visit our blog for more safety resources.

Contact one of our experts to get started on your next machine guarding project. Until then, browse our complete catalog to see our offerings.

Square Group LLC

Proud Manufacturers and Suppliers of ROBO FENCE®