Effective guarding keeps workers safe and protects equipment from damage, but only if it’s well designed. If they slow down operations, there’s a risk of being bypassed, which negates their purpose and could lead to accidents and OSHA violations. These problems are avoided by thoroughly exploring guarding options during the project’s design phase, including risk evaluation.

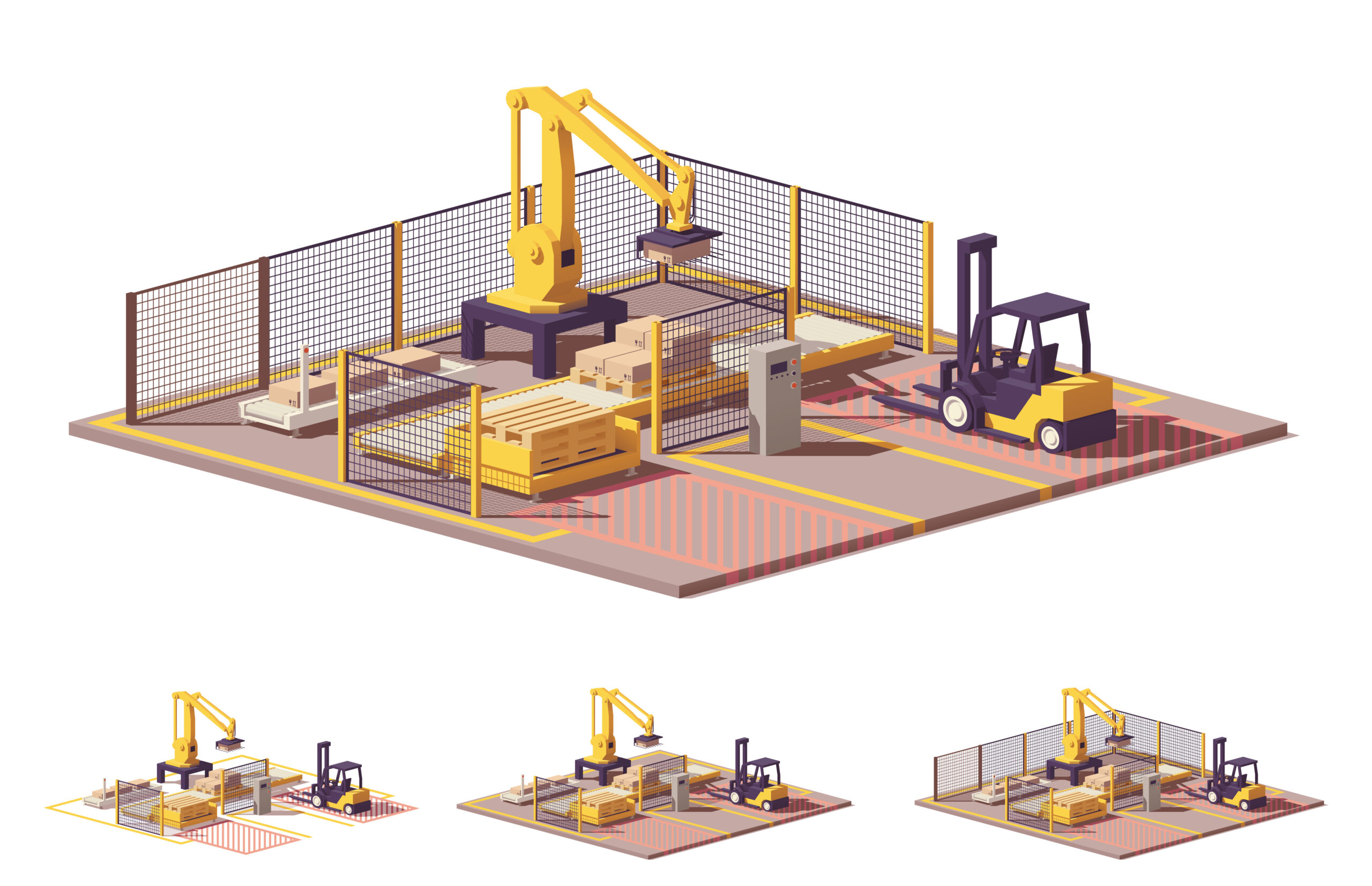

Safety guard fences for robotic cells pose particular design challenges. Robot working envelopes can mean pushing guards back further than desired, creating larger cells than perhaps expected. Access points can be another significant design challenge because they can increase the amount of required space and even complicate maintenance procedures.

Two of the most common types of safety fencing used in robotic cells are hinged and sliding fencing. Both options can drastically improve safety, but only if they make sense for your specific cell. Let’s take a closer look.

Like a gate or door, hinged safety fencing pivots open from one side. The side that opens must be selected to minimize the inconvenience of hazards to any passing traffic. On the opening side, there’s usually a latch, or, for robotic cells, an interlock that controls access.

The opening must be sized to allow access to the widest piece of equipment that needs to enter the cell, such as a pallet or forklift. Wider gates inevitably increase the loading on the hinge-supporting pillar, which must have the necessary strength and appropriate floor mountings. Folding gates can be an option, but still pose weight issues and can require floor wheels or rollers.

Hinged fencing can be as tall as needed for safety, typically 6 feet or more. As with increased width, though, increasing height also increases loading on the support.

Hinged fencing works best where there’s plenty of room for the gate to swing through, and it won’t get in the way when opened. Floor space and gate weight impose practical limits on gate width, so this design is best used for human access rather than for forklifts.

Subject to these limitations, this style of gate works well in a wide range of robotic and other machinery safety fencing systems.

This style of safety gate moves sideways on rollers to provide access to the robot or other equipment. The rollers run in a floor-mounted track, and the system can be powered to simplify operation. Latching must be considered carefully to ensure the gate closes securely and is not opened at the wrong time.

If the fencing is designed in a way that allows the gate to move parallel to the fencing, this approach requires very little floor area. However, layouts where the gate sides out into an exposed area can leave it vulnerable to damage. Plus, the floor track can pose additional safety hazards.

Select this style of access fencing for robotic safety cells when floor area is at a premium. While more expensive than hinged fencing, it supports the creation of the larger enclosures robots need to accommodate their work envelopes.

Sliding fencing is also ideal when a large safety system opening is desired. This is common when forklift access is needed to bring in large or heavy tooling, or when a robot may need replacement.

The priority placed on saving space and the opening width needed will most likely direct you toward one solution over the other. However, a risk assessment should always be carried out before making any design decisions. These assessments will help you identify other factors to consider, and perhaps highlight additional advantages or limitations of each.

Two other factors to consider, in addition to space and opening, are the need to integrate into existing systems and the systems’ load requirements.

When adding a gate to an existing system, there may not be enough room for a hinged fence to pivot fully. This could create a number of safety hazards, and so should steer you towards a sliding panel. Conversely, if space is available, the hinged gate may be easier to install.

Lastly, large hinged gates are heavy, increasing the load on the supporting uprights. This will often make the sliding approach a better option, especially in retrofit situations.

Safe operation is not possible without guarding, but they also shouldn’t interfere with maintenance and daily operations.

If you need help designing solutions for your workplace, contact our experts at ROBO FENCE®. We offer an extensive range of U.S.-made panels, safety gates, and related robotic cell safety equipment, as well as consultation services.

Contact us today to get started with your project!

Contact one of our experts to get started on your next machine guarding project. Until then, browse our complete catalog to see our offerings.

Square Group LLC

Proud Manufacturers and Suppliers of ROBO FENCE®