If you’re responsible for factory operations, machine guarding maintenance should be high on your list of concerns.

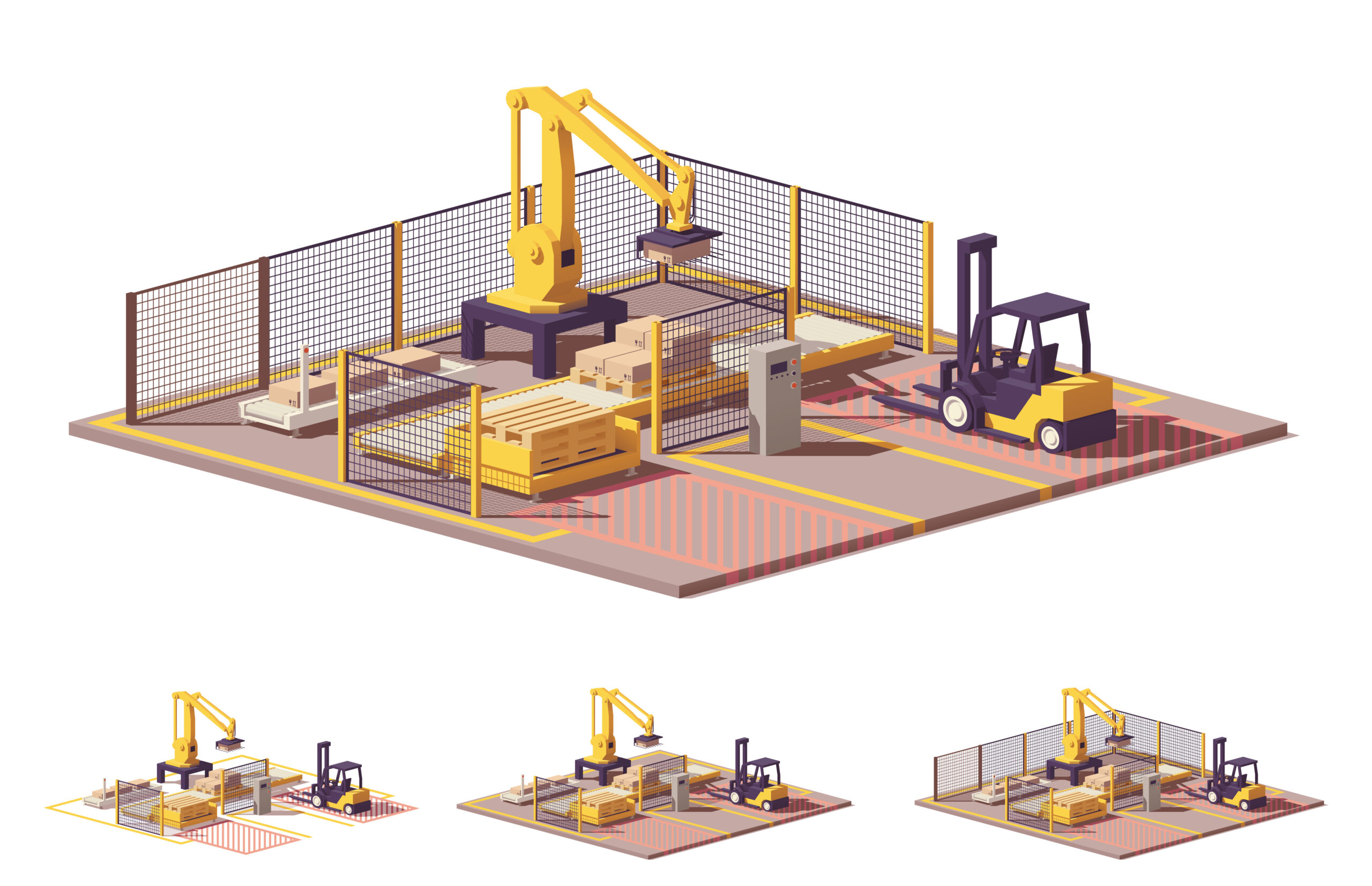

Fencing, among other factors, is critical to ensuring worker safety and preventing serious, life-threatening impact injuries from robotic systems. But, if the guarding isn’t maintained and the fencing panels, posts, or gates experience structural issues, the risk of injuries and other incidents increases.

Although fencing doesn’t require a lot of maintenance, there are still some best practices operation managers should expect to follow throughout the year, including:

A first-use inspection is essential before a cell or system starts up, and it should be repeated daily while the cell is running. The primary purpose is to verify the integrity of all guards, covers, shields, and fencing that prevent people from harm.

According to ISO 14120 (Safety of machinery — Guards — General requirements), these items must be rigid, stable, and fit for purpose. A particular concern is the risk of impacts by objects accidentally released from the robot’s end-of-arm tooling.

Other points to check for are loose bolts, gaps, misalignments, and any unauthorized modifications.

Damaged or worn parts should be replaced immediately because they reduce the effectiveness of the fencing around a robotic system and increase delay, which then increases the risk of an accident. The same applies to any guards or polycarbonate screens that have been struck or become obscured through poor cleaning practices.

Whenever any part of a robotic system is altered or upgraded to improve access or resolve another issue, it’s important to verify that guard openings and clearances still comply with ISO 13855 (Safety of machinery — Positioning of safeguards with respect to the approach of the human body) requirements. This verification is performed using a Guard Opening Scale, also known as a “Gotcha Stick.” If the “Gotcha Stick” shows a potential problem, the fencing should be repositioned at a safe distance, replaced, or both.

Lockout/Tagout (LOTO) ensures a machine or robotic system is safely de-energized before any maintenance work is done. It also prevents unauthorized energization. It’s an important practice in many aspects of machine maintenance, but especially so when working on a robotic system.

Removing movable guards that are attached to fences or machinery is often required for maintenance. In many cases, maintenance teams may need to override safety interlocks to make repairs and adjustments. In this scenario, the primary risk is that the system will be restarted before the guards are replaced. LOTO ensures the system isn’t restarted until everything has been replaced.

When maintaining robot fencing or working on any other aspect of a robotic system, good documentation is essential. By creating a record of any problems found and documenting the actions taken to address them, you can maintain compliance with industry standards, such as ISO 14120. Documentation also helps support future maintenance work or engineering changes and can provide valuable evidence in the event of an accident.

ISO 14120 requires that any fasteners used to secure fences, guards, screens, and covers be reinstalled correctly and never misplaced. If the fasteners aren’t reinstalled correctly, the structural integrity of the fencing will be compromised, thereby reducing safety.

Methods of achieving this include using captive nuts and screws, lanyards, quick-release latches that remain with the removed part, quarter-turn fasteners, and toggle clamps.

Risk assessment is a fundamental component of modern safety practices. Whenever the fencing around a robotic cell is modified, a risk assessment is required to identify and address any new hazards that may pose a safety risk.

ROBO Fence® engineers custom machine guarding solutions, including posts, panels, gates, cable tray support brackets, and entire assemblies. We also provide installation assistance and ongoing support for our customers. All products we carry have passed ISO 14120:2015 Annex C impact testing, meet CE safety inspections, and comply with the Machinery Directive and current OSHA standards.

Please contact us today if you need help designing a solution for your facility, or visit our website for more resources and tips.

Contact one of our experts to get started on your next machine guarding project. Until then, browse our complete catalog to see our offerings.

Square Group LLC

Proud Manufacturers and Suppliers of ROBO FENCE®