Machine guarding is intended to protect workers from accidents and injuries. Unfortunately, it’s not always installed, maintained, or used correctly, and when this happens, people can get hurt, and sometimes even die.

According to OSHA, nearly 18,000 workers suffer serious injuries each year as a result of guarding problems, and over 800 workers die. This is why OSHA inspectors look closely at guarding when reviewing machine safety, and will issue citations as needed.

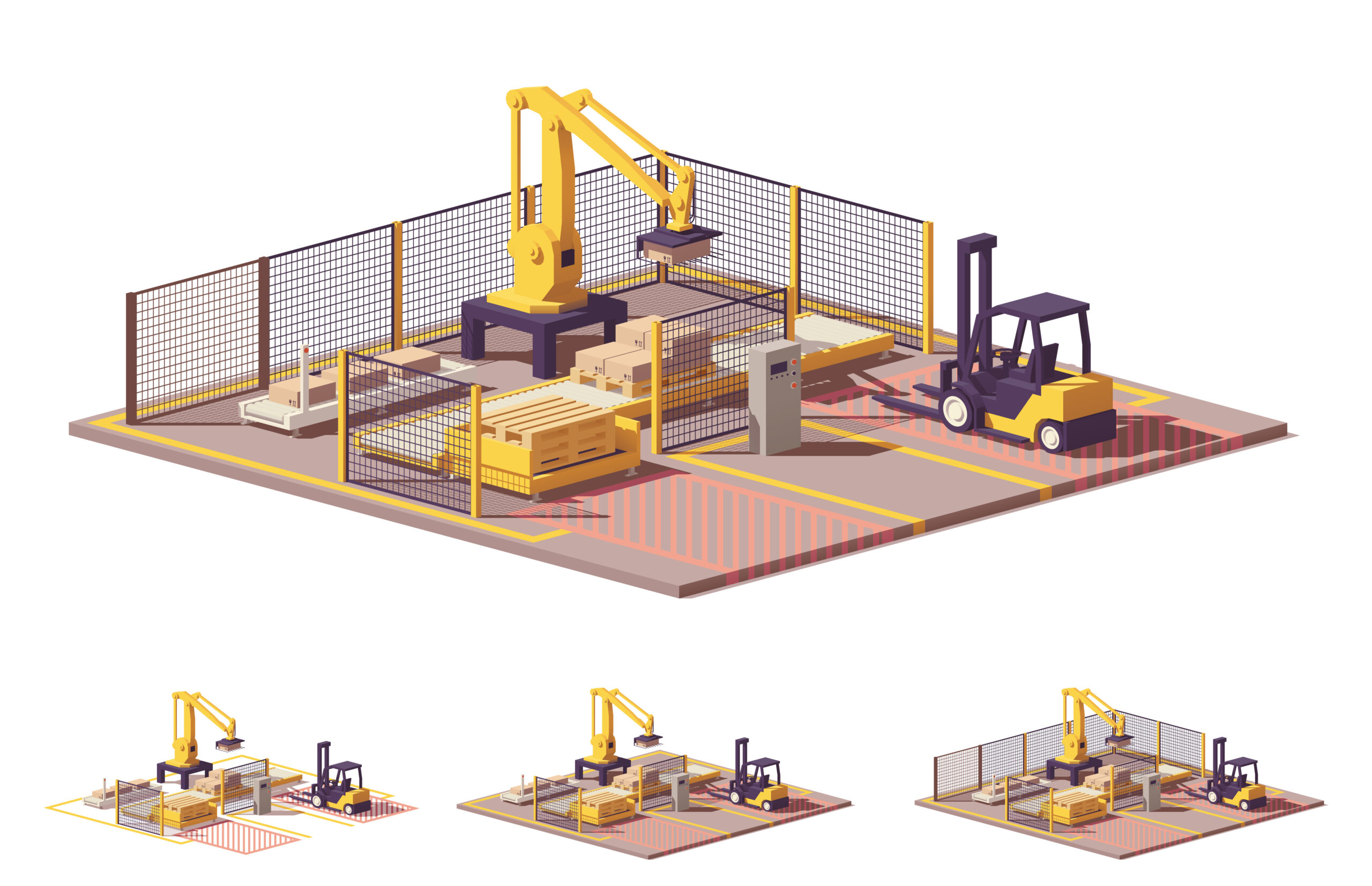

Furthermore, machine guarding violations are consistently on OSHA’s list of most frequently cited standards. It’s a widespread problem that needs more attention than it gets. And, to make matters more challenging, industrial equipment keeps changing, creating new risks along the way. Laser systems, 3D printing, and robotic cells are examples where new technology requires deeper thinking about guarding than has been the case in the past.

OSHA standard 1910.212 stresses the importance of machine guarding, but lacks detailed recommendations. For those designing and using machinery, ANSI B11.19 is a good resource, but it still doesn’t ensure complete compliance. Plants are busy places, people are under pressure, and things can and do go wrong.

Interlocks prevent machinery operation while guards are not in place or not positioned correctly. Many machine tools, such as lathes, use interlocks to verify that the guard is closed before the spindle starts turning or other operations go underway.

Interlocks are also widely used on cages around robot cells and other equipment with multiple moving parts. They ensure access doors are closed before operation begins, although they may also need lockout/tagout procedures to ensure doors are not closed at the wrong time.

Guards around power transmission equipment, such as belt and chain drives, also benefit from interlocks. As with other applications, they stop any motion when the guard is not in place.

Interlocks ensure guarding is used as intended and so prevent accidents. If a machine can run without guarding in place, it is contravening the 1910.212 standard.

Safety procedures are needed for the workers who operate equipment and for those who carry out maintenance. They detail what should be done, and in what sequence, and were developed to help keep everyone safe.

OSHA, ANSI, and other regulatory bodies report that more accidents occur during cleaning setup/changeover and maintenance than during normal operation. This is because guards are often removed to provide access while non-standardized activities are performed. Plus, if guards are not subsequently reinstalled correctly, the equipment runs in an unsafe condition.

To address the risks involved in working on machinery and the importance of using and installing/reinstalling guards, it’s critical that procedures are developed and documented. If these aren’t available, there is a very high risk of insufficient guarding being in place and operational, which would warrant an OSHA citation.

Safety protocols are of little use if employees don’t know where to find them and how to follow them. For this reason, lack of training is another reason for guarding-related citations.

Factory workers and maintenance staff should always know how to work safely and how to keep others safe. They should, for example, be able to operate emergency stops, understand interlock operations, and follow lockout/tagout procedures. They should also understand the risks of the equipment they are working on (fumes, corrosive liquids, flying particles, moving components, etc.) and know where and why guards are installed and how to use them.

If equipment or safety protocols are changed, updated, or new training should be provided immediately.

Not providing appropriate training in the use of machine safety devices and equipment is little different from not having any. There is still a significant accident risk, making this a guarding violation.

Standard industrial machinery built in quantity for standalone use is almost always supplied with guards. Where the situation becomes less clear is when machinery is custom-made and/or integrated into automated and semi-automated lines or cells. Robotic cells are a prime example because they require complex guards that integrate with the machines in the cell and with the feeding in and out of material. They are often custom-installed by the machine builder or integrator, and as a result, there is more potential for guards to be omitted. Doing so creates a number of potentially serious risks and is, therefore, a guarding violation.

Guards and interlocks can’t prevent accidents if they don’t work. Responsible employers make safety equipment audits part of their preventive maintenance program to prevent this from happening. They even include it in shift handover checks, so the incoming team knows the safety devices are all fully operational.

If OSHA inspectors were to make a visit and find guards or interlocks in poor condition or unusable, that would be grounds for a citation. To avoid this, follow recommended best practices for maintaining guarding and implement an audit log in place that tracks when systems were last checked.

The only way to build real confidence in the effectiveness of worker safety measures and avoid machine guarding violations is through regular risk assessments, followed by priority action as needed.

Beyond risk assessments, avoiding guarding violations and keeping employees safe takes quality industrial safety fencing and interlocks that are well-installed and well-maintained. ROBO FENCE helps industrial businesses achieve these goals by providing reliable guarding solutions, expert advice, training, specialist design and installation services, and ongoing support.

If you need better guarding solutions, contact one of our experts at ROBO FENCE® today.

Contact one of our experts to get started on your next machine guarding project. Until then, browse our complete catalog to see our offerings.

Square Group LLC

Proud Manufacturers and Suppliers of ROBO FENCE®