Safe, robust, easy-to-use machine guarding requires a careful design. Some engineers still like to start this process with pencil and paper, but most go straight to CAD.

CAD can be split into (relatively) inexpensive 2D systems and costly 3D systems. Both are suitable for designing industrial guards, but their strengths and limitations differ.

2D

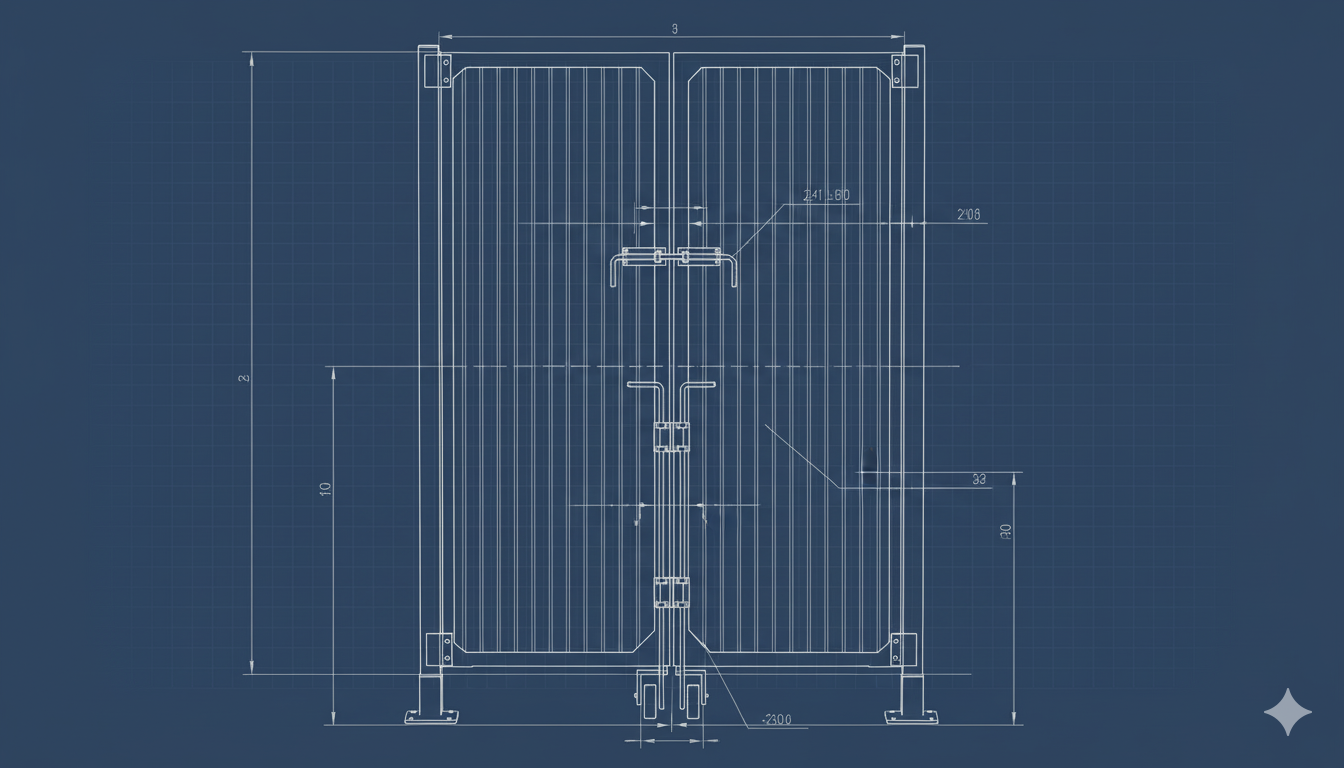

2D design is the older “traditional” style of engineering used to create flat drawings of shapes from three (or more) orientations. These drawings will often have dimensions applied to key features, and they may also incorporate “isometric” views that show how the part will look from a particular angle, so in that sense, they may offer a third dimension.

Advantages

- Communicates key information about a product.

- Can be created relatively quickly.

- A mostly inexpensive process.

- Drawings can be printed and viewed without a screen.

Limitations

- Can be difficult for non-technical viewers to understand what they are seeing.

- Can’t accurately reproduce or describe complex 3D geometry.

- Often impractical for displaying complex assemblies because they would require many 2D drawings.

Best Use Cases

- Detailed descriptions, especially of dimensions, of individual part requirements to manufacturing operations (e.g., turning and milling).

- Quickly creating drawings to indicate what a part or an assembly could look like.

- Showing where machine guards and uprights will be positioned on the floor and how doors will open.

- Producing technical documentation.

3D

3D design is used to create objects that can be rotated and viewed from different angles. So, a ball wouldn’t just be a circle on a piece of paper, but a representation of an actual sphere that can be rotated to reveal what’s written around the surface.

In CAD, 3D design is often called parametric modeling, which refers to how a change made in one feature creates changes in every related feature. It’s a lot more complex than 2D, so it requires more sophisticated software and a powerful computer to handle the dramatic increase in calculations.

Additionally, most 3D design software can create 2D drawings that can be printed out and used in manufacturing.

Advantages

- Creates pictures that can be viewed from different angles.

- Shows how complex assemblies go together.

- Can be readily understood by non-technical viewers.

- Can define complex 3D surfaces.

- Can be animated to show motion.

- Can form the basis of simulation studies.

Limitations

- Takes more time to produce drawings.

- Requires more expertise to execute.

- 3D drawings must be converted into 2D to create precise documentation for manufacturing and record-keeping.

- The software is expensive.

Best Use Cases

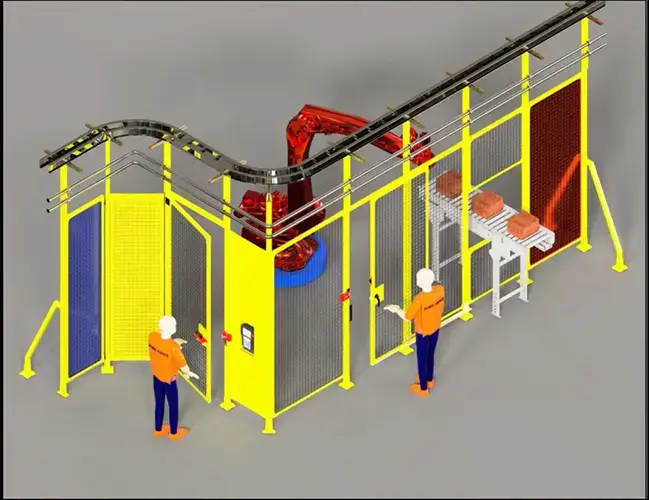

- To show a non-technical audience what a proposal or design will look like.

- When the impacts of motion need to be assessed.

- For detecting interferences and overlaps in a design, which is especially important when guarding complex workspaces like robotic cells.

- When the product or design has complex curves that are difficult to show in two dimensions.

- When further modeling or simulation is planned.

Important Elements When Designing Machine Guarding

Both 2D and 3D are suitable when using CAD design for guarding projects, subject to the limitations listed above. However, you should always consider:

- Machinery Dimensions & Exact Distance to Danger Zones: Collisions with moving devices, such as robotic arms and gantries, must be avoided, and appropriate space must be provided. Approximations are insufficient to ensure safety. Either download CAD files from vendors or use exact dimensions.

- Mounting Points: Guards must be secured to the floor, to columns, and to other panels in a robust manner. This requires knowing the exact location of mounting points.

- Industry-Regulated Safe Distances: Hazardous equipment must be far enough from guards so that objects can’t be pushed into dangerous regions, or so that spray, fumes, or debris can reach people working nearby.

- Access Openings: This refers to the openings for workers that allow access to the equipment in the cell or machine, and openings that let product enter and leave. Both must be sized appropriately and positioned in ways that ensure the guarding is easy to use, yet effective.

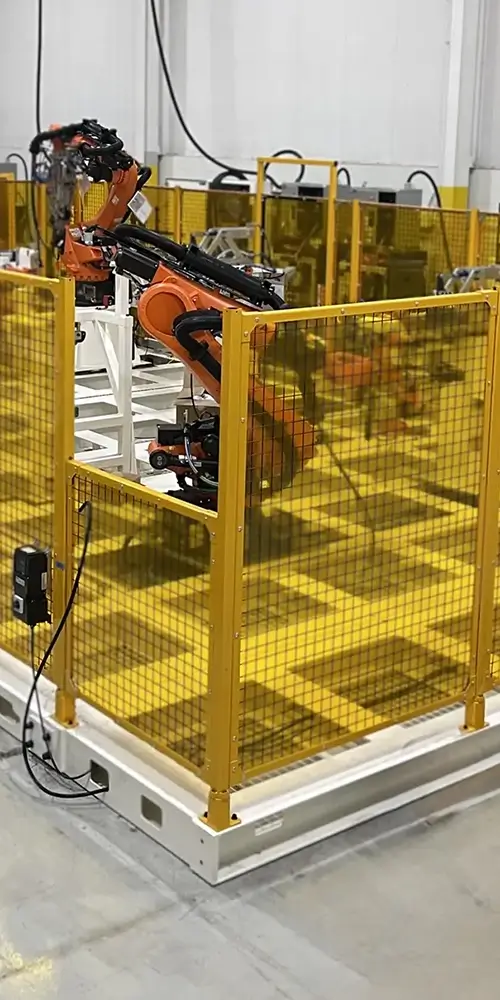

- Material Type & Thickness: Consider what is being contained or enclosed and the risk of impacts. Robots, in particular, can strike guarding with high force if there is no way to keep it out of the machine’s working envelope, so in such cases, materials should be chosen carefully.

- Interlock Locations: Interlocks are critical parts of a machine guarding system. Their locations need to be considered from the very beginning and not added as an afterthought once installation is completed. The locations need to be easily accessible to workers, but not so accessible that they could accidentally be turned off and on.

Get Help Designing Your Guarding

Rather than waste time pursuing (and implementing) ineffective solutions, partner with ROBO FENCE®.

ROBO FENCE® offers all the materials you need to create a safety system, including posts, panels, and gates. All products are manufactured in the United States through our partner, Square Group LLC. We also provide design and consulting services, with 2D and 3D capabilities.

Visit our website to learn more about our products or contact us today to get started with a design consultation. If you want to do your own design work, please browse our library of 3D CAD models.